To understand how concrete is provided to the tower, very first determine the steps of the concrete pump.

In the process of pumping concrete, the piston in the hydraulic cylinder in the hydraulic system, respectively in the two cylinder reciprocating motion backward and forward, driven by the piston rod piston in the concrete cyndrical tube, the concrete in the receptacle and also pumped along the laid pipe pump, via the pressure action to the building requires.

Next, let’s have a look at how the globe was utilized to develop the Burj Dubai!

Dubai Tower Introduction

Burj Dubai is 828 meters high, with a complete financial investment of more than $1.5 billion, slowly making use of light steel framework from 156 floors, with concrete pumping to 611 meters on the 160 floor.

Concrete Quality Number As Well As Total Quantity

Level 26 (95m)

Walls: C80A (20mm)

Pieces: C50

Level 126 (452m)

Walls: C80 (14mm)

Pieces: C50

Level 160 (611m)

Wall Surfaces: C60 (14mm)/ C80 (14mm)

Pieces: C50

Facility Core (611m) 68771m3

Wing South (502m) 36541m3

Wing East (442m) 31419m3

Wing West (390m) 27743m3

Overall: 164474m3

Secret Technological Points Of The Burj Dubai Concrete Pumping Plan

( 1) Supply the pumping equipment that can be pumped to an elevation of 611 meters.

( 2) A pumping pipeline that can endure such a high pressure.

( 3) The addiction and securing of pipes should minimize the loss of stress.

( 4) Pipeline replacement as well as cleaning.

( 5) The concrete proportion that meets both the strength needs and also the pumping requirements.

( 6) Temperature control and also setting time control of concrete.

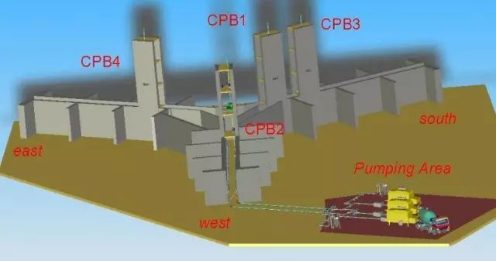

Burj Dubai Concrete Pumping Plan

Putzmeister Site Devices:

Two UHV hauling pumps BSA 14000 SHP-D

1 high-pressure pump, BSA 14000 HP-D

3 collections of 28 m cloth pole MX 28-T

3 sets of 28 m cloth poles

1 set of 32 m cloth pole MX 32-T

Regarding 1700 m ZX 150,250 bar high pressure tube

cut-off valve

Unique cleaning equipment

The concrete pump design site requirements

Concrete pump setting place, the site needs to be smooth and also solid, the roadway is smooth, practical product supply;

Near the pouring site, practical for procedure, easy to match the pipeline;

Near to drain centers and risk-free and also reliable supply of water and power supply equipment;

Tiny interference with other mechanical as well as hand-operated construction procedures;

Within the procedure series of the concrete pump, there shall be no barriers such as the high-voltage line.

Setup of the pulling pump

Delivery pipe plan

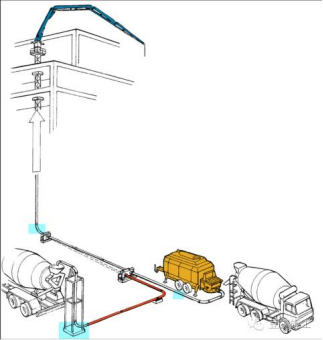

Link setting of the concrete pump as well as the delivery pipeline:

( 1) Straight connection: the conveying pipeline and the concrete pump right into a straight line

( 2) U-shaped link: that is, 180 is attached, as well as the outlet of the pump is linked to the communicating pipeline via two 90 bends

( 3) L-shaped link: the electrical outlet of the pump is connected to the communicating pipeline via a 90 bend pipe, which is perpendicular to the concrete pump

Layout of towel pole

Cloth rod:

( 1 ) Manual cloth rod RV10, appropriate for floor concrete towel, industrial plant concrete towel, require to be relocated by tower crane, low cost, and also made use of with the drag pump

( 2) Fixed cloth rod

Version: MX 32-4 (32 m 4 arms), MX 31-3

Relevant to: (1) skyscrapers, which can be climbed

Applicable to (b) infrastructure, nuclear power, industrial plant, chemical industry, etc.

Pumping system: hauling pump + distribution pipe + circulation rod.

Specifically developed pumping devices.

BSA 14000 SHP-D Ultra-high pressure pump attended to very top-level jobs.

The 470kW Caterpillar engine.

The maximum electrical outlet concrete pressure is 40MPa

The academic optimum variation is 71 cubic meters/ hour

Exactly How To Set Up A Concrete Drag Pump

Compute the pumping concrete stress according to the pumping distance and also elevation

Beginning pressure of 20 bar

- Total pipeline length per 10m 1 bar (total length = straight pipe length + vertical pipe length)

- Upright shipment tube every 4m 1 bar

- 1 bar per 10 bars.

- 90 degree bend 11 bar

- 45 degree bend 10.5 bar

- Tail rubber pipe: 1 item of 2 bar

- Safety and security get of 10%

= gross pressure

Fabric rod without weight needed

MX 32-T without weight (facility core)

3 × MX 28-T without weight (wings)

Wear-resistant ultra-high stress line

The ZX type DN150 delivery pipe

The wall thickness gets to 11mm

The cross-sectional location raised by 44%, and also the stress decreased by about 25%

Capacity to withstand a pressure of 250bar

ZX type interface, better sealing efficiency

Transmission pipe system

Pipe addiction device

Unique line replacement tool

When pumping to the acme, the primary pipeline plus concrete weight goes beyond 55t!

Putmeister established specialized training tools

The whole upper pipeline is lifted by the hydraulic cyndrical tube, and the lower pump pipe can be replaced.

25MPa stop shutoff

Quit valve: in the skyscraper pumping, the application of stop shutoff, utilized to prevent concrete backflow, when the concrete blocked pipeline with the quit valve to shut the concrete, and then treat the obstructed pipe.

Pipe style principles

Must reduce the length of the pipeline, utilize much less bending pipe and tube;

When piping vertically upward, the length of the ground horizontal pipeline ought to be more than 15 meters, the 180 level bending pipe needs to be set at the outlet of the towing pump, and the quit shutoff ought to be evaluated the sharing pipeline 3|6m at the concrete pump discharge port;

Horizontal pipe should be fixed firmly with bracket, system cushion, wall mounts and so forth at a certain range;

The vertical pipe should be dealt with at the staying opening in the top of the wall surface and column or flooring with ingrained components, as well as each pipe on the wall as well as column will not be less than one fixed point;

In each flooring plate scheduled opening needs to be taken care of;

The aggregate is less than 1/ 3 of the pipe size, as well as the 125 tubes can only be 40mm gravel;

High pressure pumping with high pressure pipe, concrete pumping is challenging can be changed by a huge diameter sharing pipeline;

No slurry shall leakage at the clamp of the pipeline joint.

Cleaning Tool

Concerning 15m3 concrete needs to be cleaned for pumping to maximum.

Repetitive examination of validated concrete ratio.

Putzmeister’s experienced experts and also customers have actually created a concrete that satisfies both the strength needs and has great pumping performance.

What requirements must the pumping concrete be satisfied (fluidness, communication, water retention).

Ratio of the maximum bit dimension of the coarse aggregate to the shipment tube size:

When the pumping height is listed below 50M, the crushed rock must not be above 1:3 and also the pebbles need to not be above 1:2.5; when the pumping elevation is 50|100M, it must be 1:3|1:4; when the pumping height is above 100m, it needs to be 1:4|1:5;

Fine accumulation should be moderate sand, sand with 0.315 mm sieve opening, should not be less than 15%, the sand rate is 38%|45%;

Pump concrete need to be mixed with suitable amount of fly ash or ore powder as well as other admixtures to improve the pumping efficiency;

Pressure bleeding examination, the family member stress bleeding price at 10S S10 should not go beyond 40%;

The dose of concrete + admixture (such as fly ash) is greater than 300kg;

The ratio of water as well as cement (glue) is 0.4|0.6;

Depression of 100-220 mm;

Option worth of concrete downturn for different pumping heights:

Pump elevation (m) below 30 and also over 30|60 60|100 100

Slump (mm) 100|140 140|160 160|180 180|200

Including an ideal quantity of pumping agent (admixture) has high efficiency water reduction, slow-moving coagulation, gas absorption effect

Substitute Problem

600 m straight delivery line to assess the taking place pressure

Calculate the pumping pressure:

Expected Concrete Stress:

C80A/20 up to 250m: 139bar

C80/14 as much as 450m: 176bar

C60/14 up to 600m: 206bar

C50/14 approximately 600m: 196bar

Real Building And Construction Website

Raw material quality control:, a part of the water is replaced with ice

Concrete temperature control: measure the concrete temperature level routinely

Concrete and also workability control: regular slump screening

Full-process expert tools upkeep

Set up the ETS remote system to recognize the working problem of the concrete pump.

Use the ultrasonic instrument to identify the condition of the sharing tube as well as learn the hidden dangers in time.

The Birth of Record

In the Burj Dubai (Burj Dubai Tower), it is typically pumped at night.

In early November 2007, after regarding 40 mins of travel in the pipeline, the concrete was pumped to an unprecedented elevation- -606 meters, as well as a new globe record of the upright concrete pumping height was birthed!