Concrete batching machine is a widely used concrete preparation equipment in the construction industry, whose core function is to accurately weigh and mix various raw materials according to predetermined proportions. This article will provide a detailed introduction to the weighing control principle of concrete batching machines.

Composition Of Concrete Batching Machine

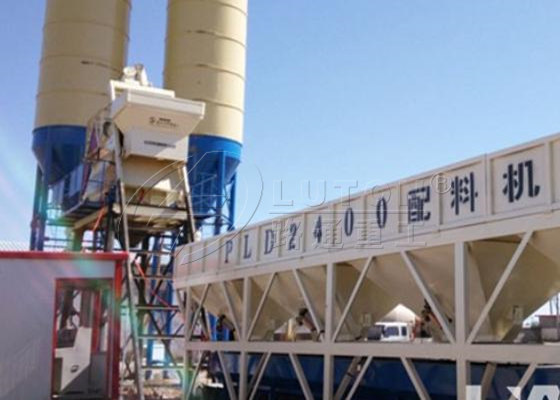

The concrete batching machine usually consists of the following main parts: storage hopper, feeding device, weighing system, control system, and mixing system. The storage hopper is used to store various raw materials, such as sand, stone, cement, etc. The feeding device is responsible for conveying raw materials to the weighing system. This weighing system is the core part of the concrete batching machine, used to accurately measure the weight of raw materials. The control system is responsible for the operation and control of the entire batching machine, ensuring the accuracy and stability of the batching process. The mixing system mixed various raw materials into concrete. Concrete batching machine is one of the most important composition of concrete mixing machinery.

Weighing System Principle

Weighing Method

Concrete batching machines usually use lever or electronic weighing methods. Lever weighing utilizes the principle of lever balance to calculate the weight of materials by measuring the displacement of the lever. Electronic weighing uses sensors and electronic technology to convert the weight of materials into electrical signals, which are then displayed on electronic instruments.

Control Principle

The weighing control system of the concrete batching machine usually adopts a closed-loop control method. In closed-loop control, the output signal of the controller directly controls the operation of the feeding device, while continuously adjusting the feeding speed of the feeding device through the feedback signal of the weighing system to ensure that the actual weight is consistent with the set weight.

Precision Control

In order to ensure the accuracy of batching, concrete batching machines usually adopt various measures to reduce errors. For example, using high-precision sensors and instruments to improve measurement accuracy. Reduce feeding errors by dynamically adjusting the feeding speed.

Automatic Control

Concrete batching machines are usually equipped with an automatic control system, which can achieve functions such as automatic alarm. The automatic control system greatly improves the automation level of the batching process and reduce the impact of human factors on batching accuracy.

In summary, the weighing control principle of concrete batching machines is mainly achieved through high-precision weighing systems and close-loop control systems. By accurately measuring and controlling the weight of various raw materials, the quality and stability of concrete can be ensured, thereby improving the safety and reliability of construction projects.